- Your gateway to the Maritime Knowledge!

- [email protected]

How and when to ventilate the Cargo Holds?

How to correctly plot the Tropical Revolving Storm (TRS)

July 15, 2020

The importance of Vessel Traffic Services

November 1, 2020This topic deals with the principles and procedures for carrying out Cargo Hold ventilation onboard Bulk Carriers.

Ventilate the Cargo Holds: Ever wondered why water droplets form on glass surface once cold water is poured inside, in hot climate?

Now you would say that this is primary school Physics and anyone can answer that. Although, the process is called ‘condensation’ it holds a very important place in shipboard cargo operations especially on a Bulk Carrier carrying a dry bulk cargo which is perishable in nature.

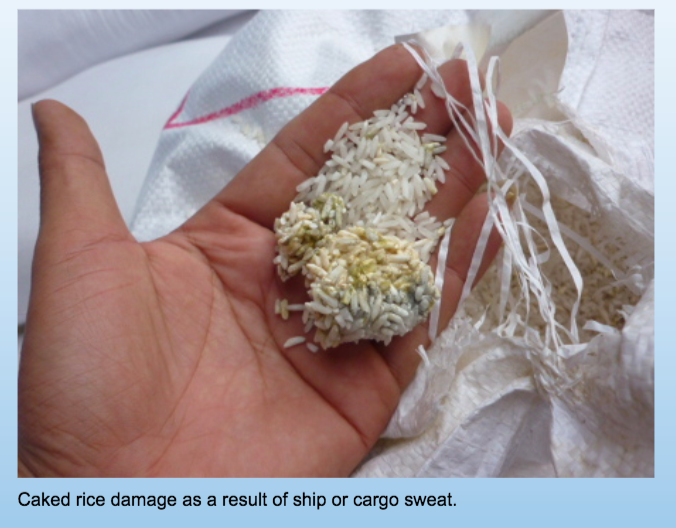

This ‘condensation’ process, if not controlled and monitored properly can result in ‘sweating’ of the cargo holds (i.e. formation of water droplets all over the cargo) and hence may result in damage to perishable goods such as grain, sugar or may even result in chemical reaction with few cargoes (such as DRI).

Hence, understanding of ‘Sweat’ is very important to Marine officers and shall be well understood by officers serving especially on Bulk Carriers. By the way, Sweat here refers to condensation.

In Marine Terminology there are two kinds of ‘sweat’ –

- Cargo Sweat

- Ship’s Sweat

Cargo Sweat

What is it?

Cargo sweat may refer to the condensation that may form on exposed surfaces of the cargo in side of the Cargo Hold. It can be depicted like this –

When does it occur?

It occurs when large amounts of warm, moist air is introduced into a hold containing substantially colder cargo. This usually occurs when the voyage is from a colder to a warmer place and outside air is allowed to enter the cargo spaces.

Where does it occur?

Inside ship’s hold over the Cargo surface

Why does it occur?

The Ship’s Hold has air has dew point which is lower than the outside air (as the ship loaded the cargo in Cold climate and is now proceeding to hotter climate). If the outside warm and moist air having a higher dew point is allowed to go inside the cargo compartment having colder air, the water vapor on the surface of the cargo condenses to form water droplets all over the cargo surface.

How to prevent this?

All ventilation should be restricted until the temperature of the cargo is above the dew point temperature of the outside air.

Remember Cold to Hot is Cargo Sweat

Ship’s sweat

What is it?

Ship’s sweat refers to condensation that forms directly on a vessel’ structure inside the cargo spaces, inside hatch covers, over frames/hatch sides as shown below –

When does it occur?

It occurs when the warm and moist air inside the hold (near to surface) comes in to contact with the cold air as the vessel moves into cooler climates.

Where does it occur?

Inside ship’s hold over the Hold’s surface

Why does it occur?

The Ship’s Hold has air whose dew point is higher than the outside air ( as the ship loaded the cargo in warm climate and is now proceeding to colder climate). The outside colder air condenses the warmer air inside the cargo hold near to the hold sides and surface as shown. (This is similar to the phenomenon of pouring cold water inside a glass on a hot day. The air outside the glass in contact with glass surface gets cooled below its dew point and condenses into water droplets).

How to prevent this?

To prevent the ship’s sweat, the holds shall be surface ventilated as long as the dew point of the outside air is lower than that of the inside air.

Both, Cargo and Ship’s Sweat may result in damage to the cargo. Cargo sweat is formed over the surface of the cargo and Ship’s sweat may damage the cargo due to overhead drip’s and accumulation of water inside the cargo holds

When you should carry out the ventilation of the Cargo Holds?

Some bulk cargoes are required to be surface/thoroughly ventilated depending upon the nature, properties and the carriage requirements of the cargo. In order to ascertain whether one should ventilated the cargo holds, the following shall be kept in mind –

Dewpoint Rule

If the dew point of both the outside and the hold air can be determined then the West of England P&I Club advises the use of Dewpoint Rule –

- VENTILATE if the dewpoint of the air inside the hold is higher than the dew point of the air outside the hold

- DO NOT VENTILATE if the dew point of the air inside the hold is lower than the air outside the hold

Whirling Psychrometer shall be used in order to determine the dew point inside cargo space and outside.

Three Degrees Rule

The three degree rule may be applied when it is impracticable to measure hold dew point temperatures accurately. In such cases the ventilation requirements may be estimated by, several times a day, comparing the average cargo temperature at the time of loading with the outside air temperature. Ventilation may then be carried out on the following basis –

- VENTILATE if the dry bulb temperature of the outside air is at least 3 deg C cooler than the average cargo temperature at the time of loading

- DO NOT VENTILATE if the dry bulb temperature of the outside air is less than 3 deg C cooler than the average cargo temperature at the time of loading or warmer

In general terms, hygroscopic cargoes need to be monitored more carefully than the non-hygroscopic cargoes.

Hygroscopic Cargoes are those cargoes which have a tendency to absorb moisture. Grain, Sugar, Cocoa etc are some examples of Hygroscopic cargoes.

Hope you liked the topic.

Wish you pleasant seas and Bonn Voyage!